Quick Heat Transfer for your Tank

When your storage or processing tank needs heating or cooling capacity that doesn't currently exist, we have the heat transfer solution for you. Clamp-on and Immersion heat transfer panels can be retrofitted to your existing tank at a lower cost than outside-the-tank units and are safer and more effective than traditional steam or electric tracing methods. Heat transfer panels can be applied to tanks that serve the chemical, food, dairy, pharmaceutical, brewing industries and many other applications.

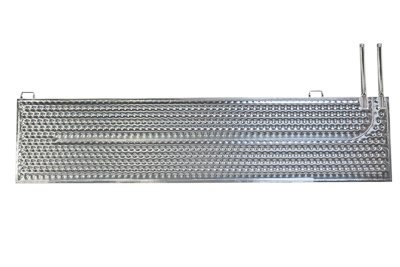

More Contact Surface

With higher contact surface, Paul Mueller Company's Temp-Plate® immersion and clamp-on panels use much less fluid media to achieve the same heating contact area as other heat transfer options. They are an optimal choice for any volume application where you have product or process fluid stored in a tank. Welded-on heat transfer and external PHE systems can be much more involved, expensive and harder to clean for retrofit applications.

Ease of Installation

Tank fabricators and engineers know, when building a new tank or updating an existing one - ease of installation and ongoing maintenance are two important factors to consider. Temp-Plate® inflated heat transfer panels can clamp on the outside of the tank or be immersed in the fluid and ready to use immediately. Depending on the level of involvement, we can install the heat transfer, piping, controls and water heating systems in as little as a day or during a scheduled plant shutdown.

Minimal Maintenance

With the heat transfer surface exposed, cleaning is easy, plus the panels can be removed for servicing and then re-attached. For even more capacity, we can provide a bank assembly with spaces that allow all particulates to flow through.

For affordable and easy heat transfer inside your storage tanks, contact Paul Mueller Company to talk through options. We can install it or provide installation guidelines to get your process back on track quickly.