| Model |

Number of Plates |

Connection |

Pump Capacity (Ltr/Hour)* |

Dimensions |

| |

|

Water (") |

Milk (mm) |

|

Height (mm) |

Width (mm) |

Depth (mm) |

Weight (kg) |

| M8A-14 |

14 |

1 |

32 |

|

740 |

180 |

171 |

33 |

| M8A-22 |

22 |

1 |

32/40 |

1500-3100 |

710 |

180 |

194 |

36 |

| M8A-30 |

30 |

1 |

32/40 |

2800-5000 |

740 |

180 |

216 |

40 |

| MD8A-30*** |

30 |

1 |

32/40 |

2800-5000 |

740 |

180 |

216 |

40 |

| M8A-40 |

40 |

1 |

40 |

4000-7000 |

740 |

180 |

244 |

44 |

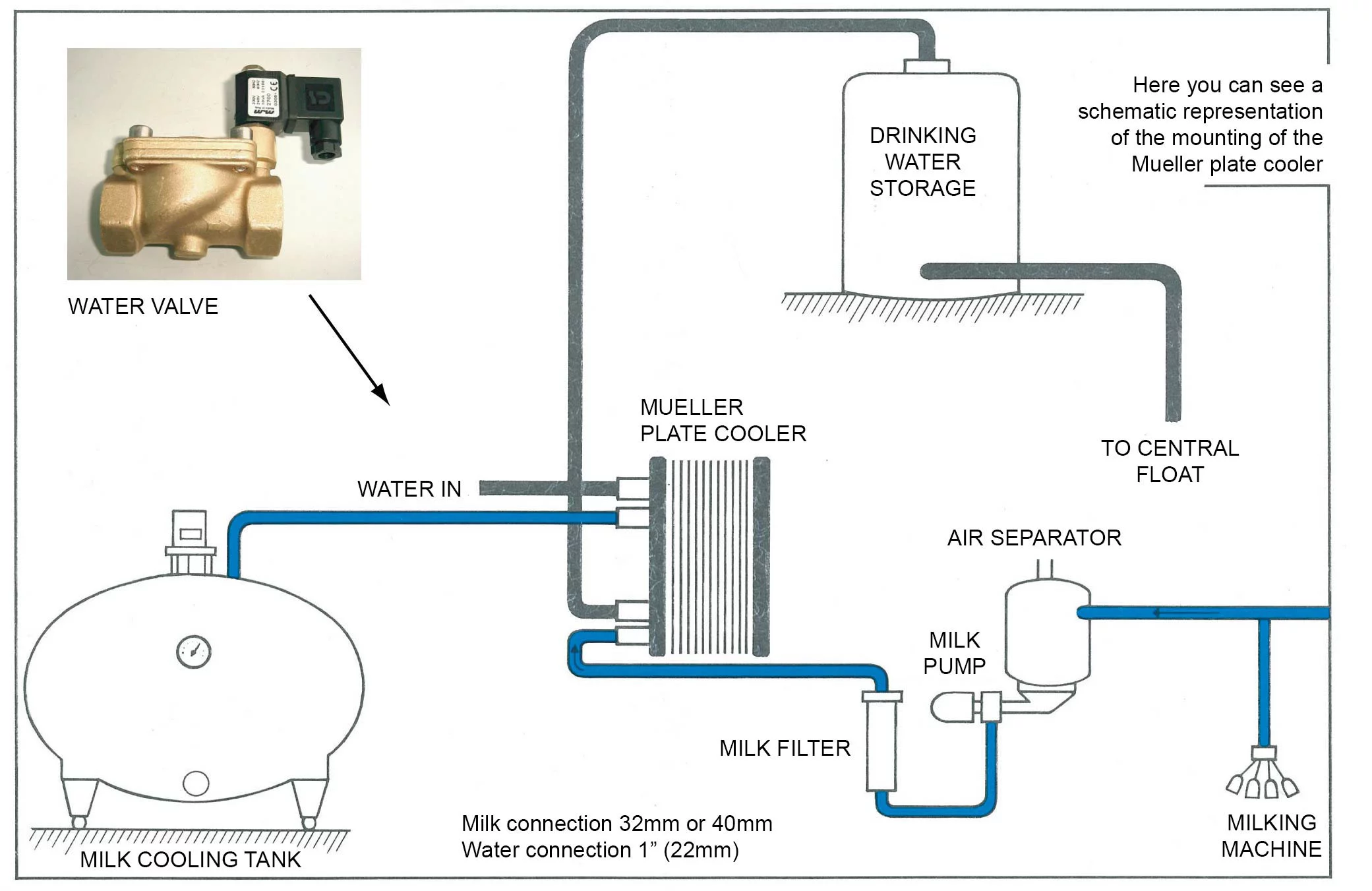

* Under operating conditions

** Distance to wall=100mm

*** The MD8A and MD8A-30 plate coolers are double walled. By using double walled plates, it is no longer necessary to check the ground water each year.

The information in this table may deviate from the actual execution. Consequently, no rights may be reserved with respect to the information contained.