This article is dedicated to identifying issues your plate heat exchanger (PHE) might be having, and setting you on the path to the right solution. Nearly all issues boil down to some form of plate fouling or gasket failure, but it’s important to determine whether it’s a one-time problem or an inherent flaw in your system (the PHE is specified incorrectly). The first step is to identify the symptoms of your underperforming heat exchanger.

Identify Symptoms

The most common symptoms are the following:

- Increased pressure drop from inlet to outlet

- Loss of heat transfer efficiency

- Loss of flow and performance

- Process fluid leakage

The first three symptoms are all typically related to plate fouling, while the last is usually due to a gasket failure. However, gasket failure or the rarer case of plate cracks can lead to any of the four, so it’s important to take some simple steps to figure out what exactly is going wrong.

Gasket Failure and Differential Leaks

When troubleshooting, it’s usually best to first assume the most likely problem, as it also tends to have the easiest and least expensive solution. The easiest problem to identify is gasket failure – if a gasket fails, the pressure will force fluid through the leak and you’ll be able to see fluid dripping out of the PHE. The fluid will drip out of the offending gasket, so you’ll be able to easily locate the failure. To fix your PHE, disassemble it and remove the plate with the failed gasket and a plate adjacent to it (to keep the flow pattern intact). Then, if you have replacement parts on hand, simply replace them, reassemble and tighten your PHE to specification and put it back in service. If you don’t have the replacement parts on hand and can’t afford downtime while you wait for shipment, you can simply close your PHE back up and put it back into service as you wait – missing two plates will only have a small impact on performance. However, be careful that you know how much to tighten the PHE with two fewer plates. Information about that should be in your manual, or can be provided by the manufacturer.

When the two fluids in a PHE mix due to equipment failure, it’s known as a differential leak.

The most common causes of a failed gasket are incompatible fluids and/or excessive pressure. Make sure your pressures are within specifications (and your system is free of potential water hammers) and the gaskets are rated for your materials. If gaskets are developing holes in them, your fluid is likely too hot or too corrosive, and you’ll need to replace your gaskets with more ones that are more adequate for your process.

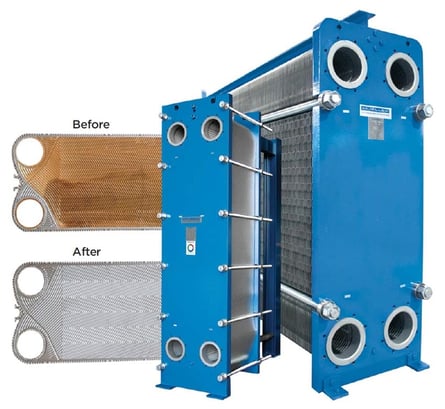

Plate Fouling and Corrosion

Plate fouling is the most common issue with PHE’s, but can be difficult to solve because it’s not generally covered for replacement under warranty. If your PHE consistently gets fouled up due to properties of your process fluid, there’s not a great deal you can do other than regular cleaning. You can talk to your manufacturer about installing plates with a wider gap, but that solution has performance and cost drawbacks, and doesn’t work in all cases. Generally speaking, a regular cleaning schedule is the best option. A clean-in-place (CIP) process is the easiest approach, but disassembling and cleaning by hand is also a possibility.

If the plates are corroded, that’s a more serious issue than simple fouling. This, too, falls in the category of a differential leak. You can put your PHE back into service the same way, but a cracked or corroded plate generally signals that one of your fluids is too corrosive, and you may experience the same problem again. Check with your manufacturer that the PHE is properly specified for your application. If all is well, then the crack or corrosion is likely a manufacturer defect, and will nearly always fall under warranty.